Service

The transition towards predictive maintenance may seem big, given its complexity. This is why we provide predictive maintenance as a service. It allows you to focus on your core business while we take care of the rest. Our approach simplifies your transition to predictive maintenance by eliminating the need for any specialised data skills.

Your transition to predictive maintenance is done in a few simple steps:

Asset selection

We collaborate to strategically select assets that will benefit from predictive maintenance, unlocking improved efficiency and extended lifespan.

Implementation

The implementation process is completed in just a few minutes, ensuring minimal disruption to your operation. Our sensors are installed without any modifications to your assets.

Monitoring

Our dashboard is designed to make your job easier. It directly shows the current status of your asset and predicts its maintenance date without needing any data expertise!

Advice

As we collect more data over time, we provide you with advises on your assets. For example, asset overloading, optimise settings like RPM or energy-saving actions.

In the background, we remain active by monitoring, updating, and adjusting the self-learning predictive maintenance system when required!

System

Our predictive maintenance system is built upon three core components. The team of specialists carefully handles the implementation and operational setup of these components.

Measuring hub

Sensors are mounted on your assets and connected to measuring hubs. Ensuring precise monitoring and real-time data collection.

Edge computing

The system uses the sensor data to predict maintenance dates. Saving the data and predictions securely on-site.

"Maintenance required over one month!"

You will be notified by the system when the predicted maintenance date is nearing.

Experience our predictive maintenance system firsthand with our demonstration!

SYstem features

The system incorporates six key features. Along with predictive maintenance, these functions give further insight into the operations of your asset.

Maintenance predictions

Our system uses machine learning models to predict asset maintenance, enabling timely scheduling and ordering of materials.

Energy management

The system provides insight into energy saving measures. Ensuring the highest achievable efficiency.

Performance reports

Monthly reports on asset performance are generated based on availability and, wear and tear.

Cross-comparisons

Compare assets based on their performance and energy consumption. Get insight into the differences and outliers.

Historical profiles

Gain valuable insights from the history; event logging, maintenance records, availability, and data trend-lines.

Get a personalised quotation and discover how predictive maintenance can benefit your business.

APPLICATIONS

Predictive maintenance is a widely applicable technique that can identify faults in various types of assets at an early stage. Examples of these assets and their faults include:

-

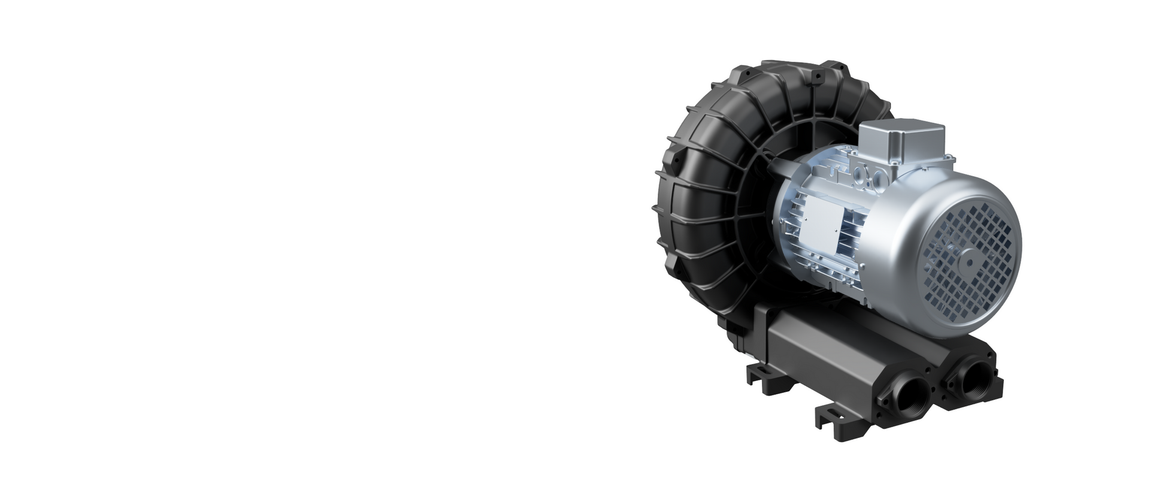

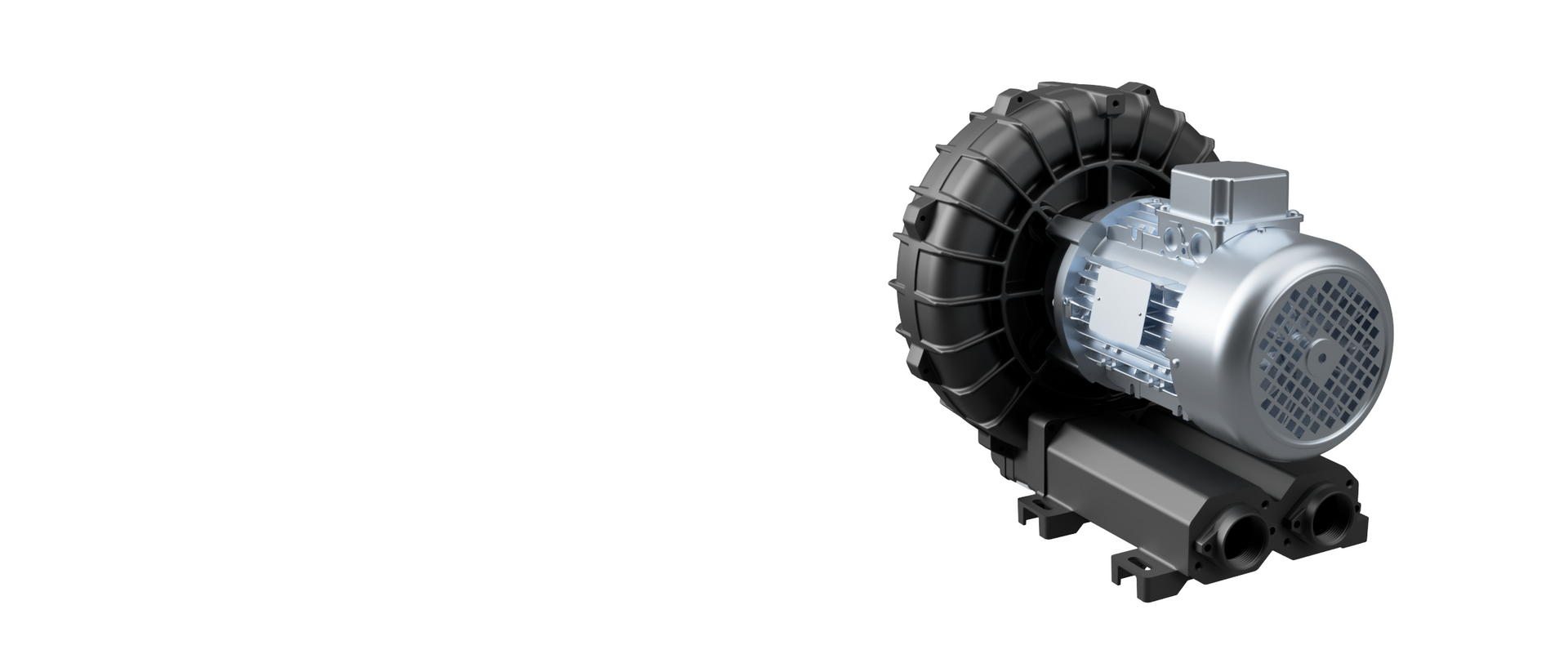

Rotating machines

- Misalignment

- Imbalance

- Looseness

- Bearing wear

- Stator wear

- Rotor wear

- Insulation wear

Knop Valves

- Sealing wear

- Disc wear

- Shaft wear

- Actuator problems

Knop

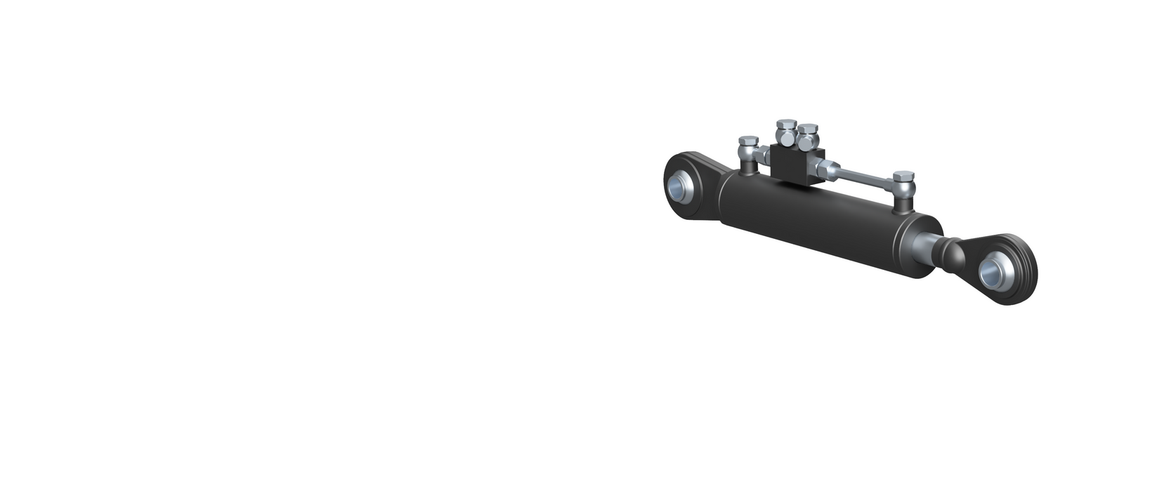

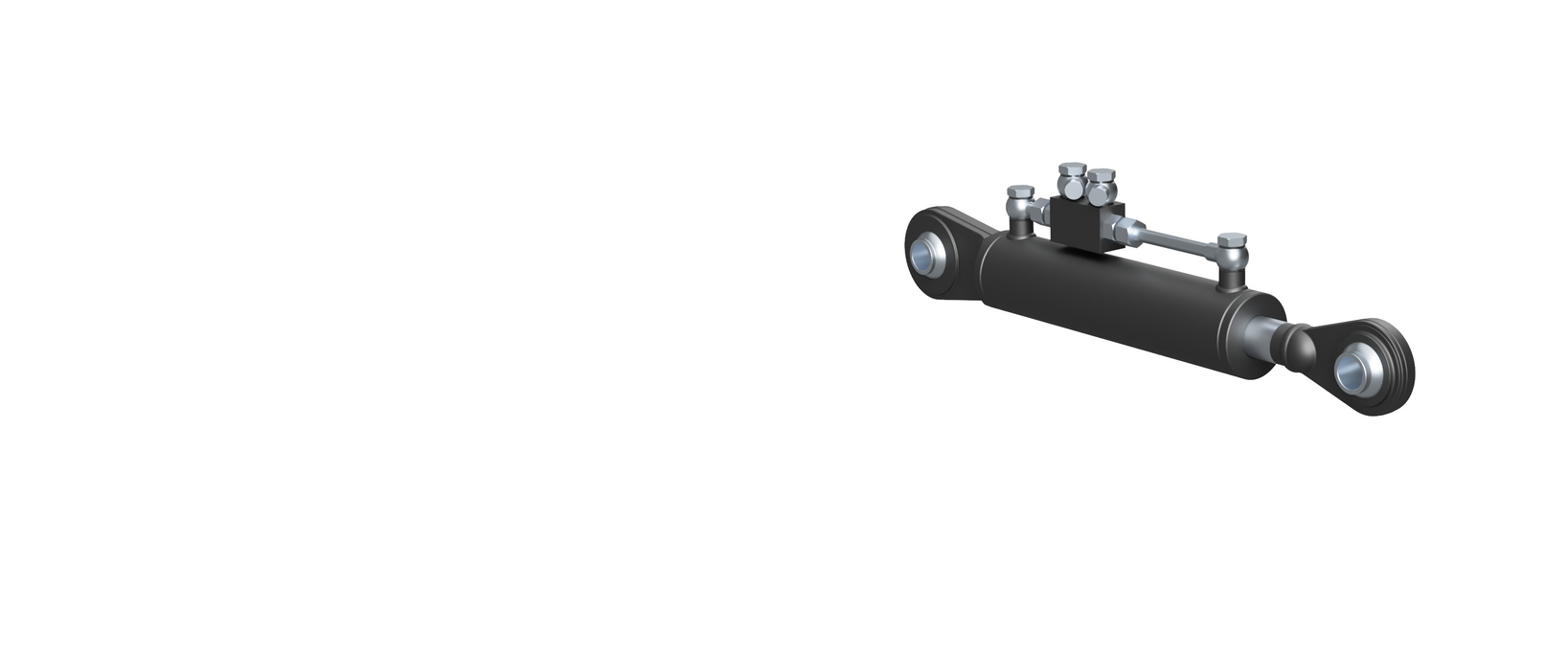

Pneumatics and hydraulics

- Leakages

- Obstructions

- Sealing wear

- Bearing wear

- Piston rod wear

- Cylinder tube wear

Knop-

More applications

The applications are endless!

Contact us for a customised solution for your specific needs.

Knop

-

Rotating machines

- Misalignment

- Imbalance

- Looseness

- Bearing wear

- Stator wear

- Rotor wear

- Insulation wear

- Load wear

Knop Valves

- Sealing wear

- Disc wear

- Shaft wear

- Actuator problems

Knop

Pneumatics and hydraulics

- Leakages

- Obstructions

- Sealing wear

- Bearing wear

- Piston rod wear

- Cylinder tube wear

Knop-

More applications

The applications are

endless! Contact us for

a customised solution for your specific needs.

Knop

Curious about how predictive maintenance works? Take a look at our blog post.